Description

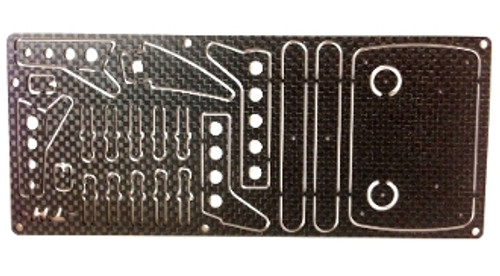

The Edge 540 V3 from RC Factory brings major upgrades to stiffness and torsion rigidity, eliminating fuselage twist during aggressive rolling maneuvers. A thicker wing handles extreme high-G stunts with ease. Pilots familiar with the 39" series will notice improved construction, including adjustable tail pushrods and new EPP bracing for simpler assembly.

Dual aileron servos are now repositioned for a cleaner layout, while outer counterbalance tabs boost roll rate and precision. The flight envelope is broader and more responsive—ideal for both advancing pilots and those seeking a durable 3D alternative to balsa. Spinner not included.

Model Specs: Wingspan: 39" AUW: 400–500g (depending on setup)

Recommended Power System: Link

Other Requirements:

Build Resources:

- Twisted Hobbys PDF Manual

- RcF Edge 540 V3 1m manual

- RcF Edge V3 2022 manual

- RCGroups Discussion

- Twisted Hobbys Review/Blog

Replacement & Upgrades:

6 Reviews

-

.

Love everything about this plane. Materials are amazing, everything fits where its supposed to fit. everything works perfectly! the build was super fun. The Procedure however, is very confusing at times. if you built one already then you should be ok but if you're new at this its going to be a little bit of a challenge. I think putting in a few comments explaining a little better would have been a big big plus and would have helped allot. I ended up gluing the "rod guide pins" on the bottom side instead of the top, procedure is very confusing in the area, you're not sure if the plane is upside down or right side up... colors are confusing compared to what you have in front of you. also, only comes with 2 longer servo horn, I needed 4... BUT, apart from this, its one of the best foam planes I have ever seen or built. its SUPER sturdy and durable. you will have fun building and flying this! I just think RC Factory can do a better job with the procedures. :)

-

Buy one. You won’t regret it

Awesome flying plane. Love every minute of it

-

39" EPP Edge 540- V3

Interesting. This is my first foamy, need to learn 3D manuvers. I normally fly Giant Scale. Qualtiy is great, quite surprising for the price. My only suggestion, is the folks follow the manual page by page, the answer is there or you need to wait to complete the next step - ithe answer to your quesation will show up.

-

Edge 540

1400 kv motor first flight no trim ,flys amazing

-

Build of RCF 39" Edge 540 - V3

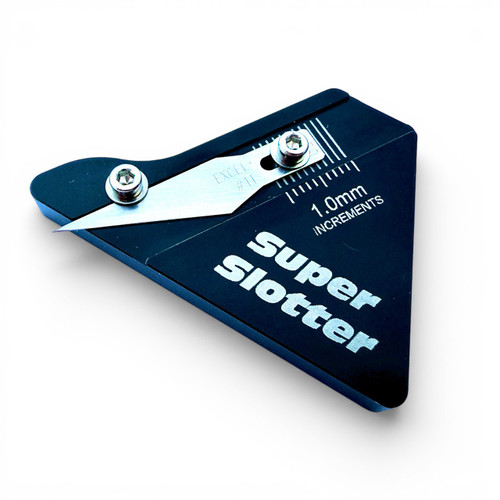

1. The side flanges on the control horns are very weak.. Only apply pressure to the very top. Once tested, run your exacto blade down the side and this will help seat the horn (also works well for the CF spars). 2. I found it better to install the links on the servo control horns prior to putting them on the plane.. a bit of a challenge afterwards... the brass clip is very small and subject to running off. Be sure to work over a tray or other catch item... 3. For the small white plugs on the clevis - It works best if you use a 3/16 drill bit and slightly enlarge the opening... Hand twist it a few times and it'll go in better. You may have to slightly sand the ends of the CF rods to go into the connectors. 4. If you take a popsicle stick; break it in half , then shave off two narrow pieces... they will slide through the alignment holes of the side force generators and hold it in place nicely until your glue sets. OVERALL - a relaxing and fun project to put together. Quality crafting by the RCF!

-

RCF 39” EPP Edge 540-V3

To me, this kit design is “almost perfect”. I believe it would be perfect if you would factory form the top and bottom wing slots instead of requiring the modeler to hand cut the slots, and provide some additional reinforcement around the overly weakened fuse at the aileron servo pockets.